Filigree: The Timeless Craft and How It’s Made

Filigree, derived from the Latin words filum (thread) and granum (grain), is an ancient jewellery-making technique that has captivated artisans and admirers for over 3,000 years.

This delicate art form twists fine metal wires into intricate patterns, creating designs that resemble lace crafted from precious metals. Historically, filigree has adorned the treasures of ancient civilizations, with notable examples found in Mesopotamia, Egypt, and Greece.

During the 10th and 11th centuries in Ireland, artisans produced remarkable filigree pieces such as the Ardagh Chalice and the Tara Brooch, showcasing the technique's enduring appeal across cultures and epochs.

At Pusaka Jewellery, we preserve this ancient art by meticulously handcrafting each piece, ensuring that the tradition lives on in the modern world. Our name, meaning Treasure or Heirloom in Indonesian, reflects our dedication to timeless craftsmanship.

Founded by Edwin Charmain, a multi-award-winning jewellery designer, our London-based studio merges heritage with innovation, embracing traditional techniques in an era of mass production.

Influenced by Edwin’s Indonesian textile heritage, each creation tells a story, honouring the past while reimagining it as a contemporary, wearable treasure.

The intricate process of filigree requires exceptional skill and patience, as each element is carefully shaped, assembled, and soldered into place. The typical process involves:

Step 01

Preparing the Metal

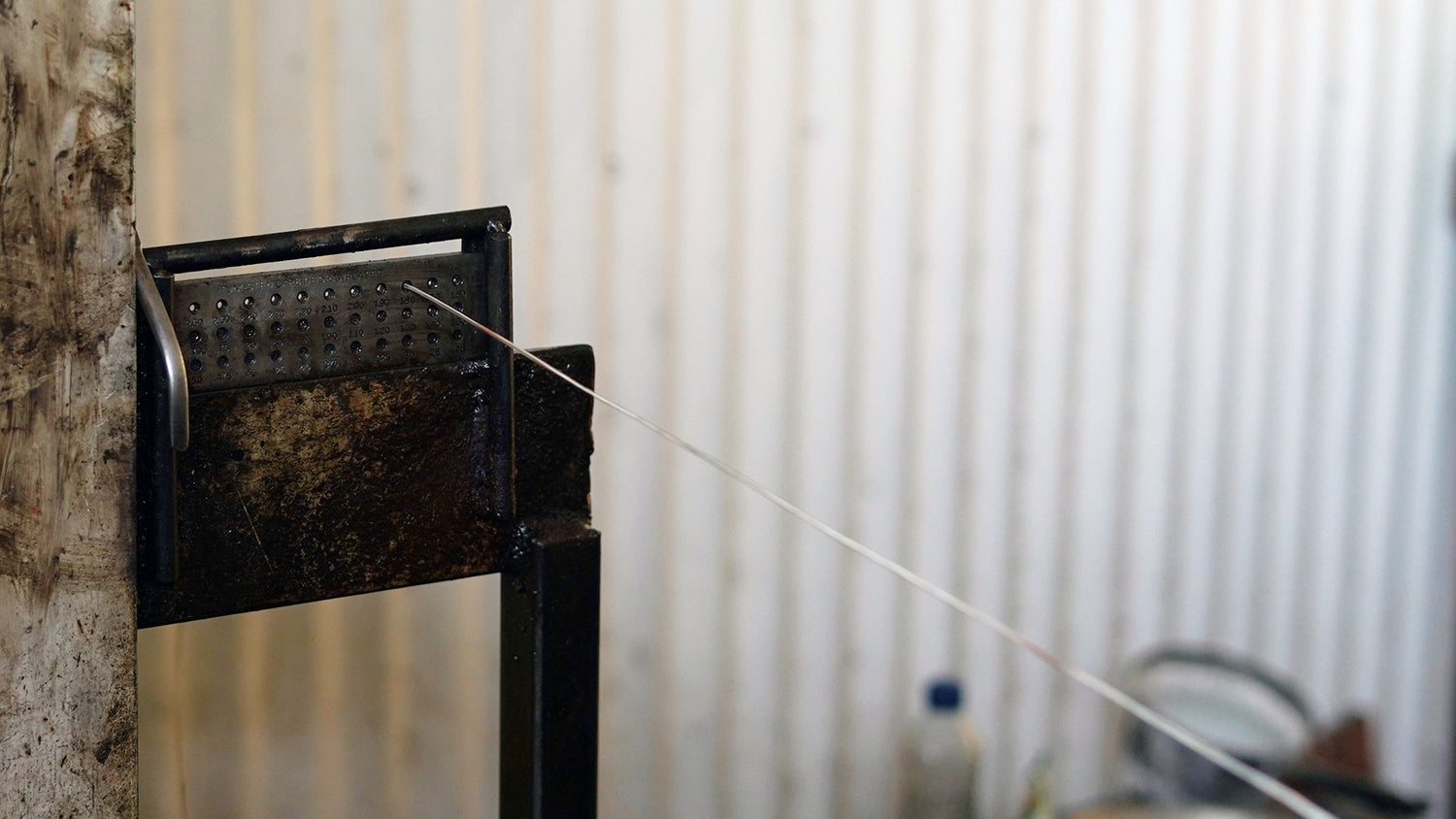

The chosen metal—often fine silver or gold—is melted, rolled into square wire, and then drawn into fine round wires using a combination of a rolling mill and a draw plate.

This drawing process is repeated multiple times until the desired wire gauge is achieved, with the wires being annealed and shaped between each stage to maintain flexibility and precision.

Step 02

Spinning The Filigree Wire

To make the filigree wire, two or more fine wires are twisted together to create delicate, rope-like strands. the twisted wire is lightly passed through a rolling mill to create a glistening silky ribbon-like effect.

Step 03

Creating the Frame

The outer shape of the jewellery piece, known as the frame, is meticulously crafted by hand-shaping thicker metal wires.

This frame serves as the foundation, ensuring stability for the intricate details that follow.

Step 04

Forming the Filigree Patterns

Using traditional techniques, the fine wires are shaped into desired motifs that could be curls, spirals, tendrils, etc.

These elements are then arranged within the frame, carefully positioned to maintain harmony and symmetry.

Step 05

Soldering the Components

Each individual wire is delicately placed and then soldered using fine precision. The heat must be controlled carefully—too much can cause the intricate patterns to collapse, while too little won’t fuse the elements securely.

Step 06

Cleaning and Refining

Once soldered, the piece is cleaned in a pickling solution to remove oxidation and any residue. The filigree is then polished and refined to enhance its brilliance, ensuring a smooth and flawless finish.

Step 07

Adding Surface Treatments (Optional)

Depending on the design, additional oxidisation, plating, enamelling, or texturing may be applied to enhance contrast and bring out the intricate details of the filigree work.

Step 08

Final Polishing and Quality Check

The last stage involves a thorough polishing by hand, ensuring the metal gleams beautifully.

Every detail is inspected meticulously to guarantee perfection in craftsmanship before the piece is ready to be worn and admired.

More than just an adornment—Filigree jewellery is a labour of love, a tribute to centuries-old craftsmanship, and a reflection of exquisite artistry.

Whether it’s a delicate pair of earrings, simple rings or an ornate statement piece, each creation carries with it a timeless elegance that is truly one of a kind.